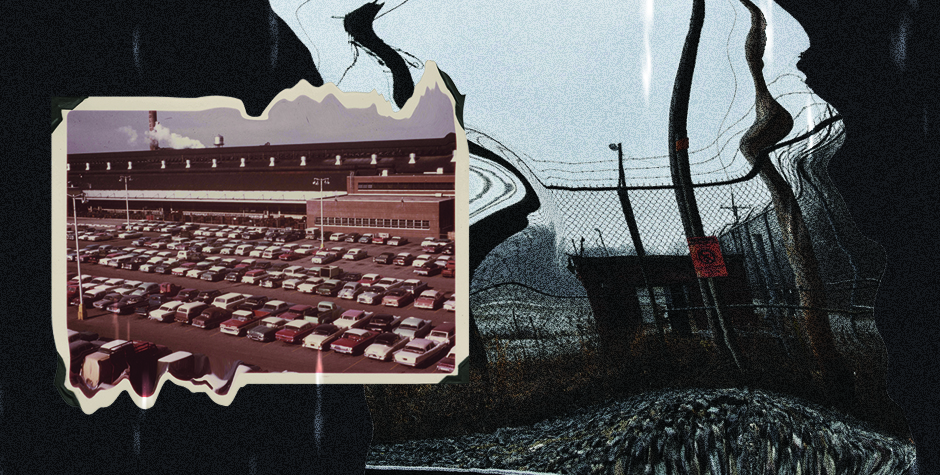

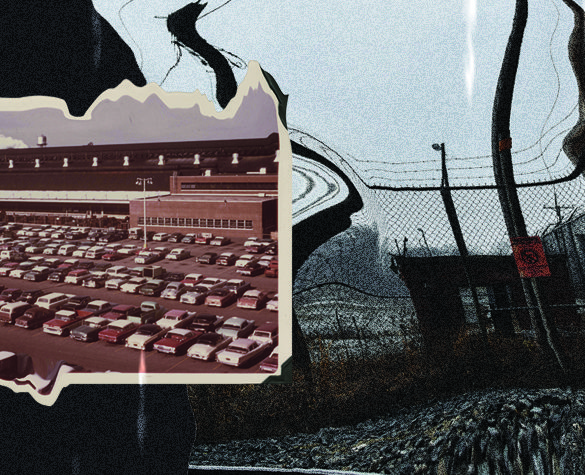

Muncie was once a factory city, but in recent years has experienced rapid deindustrialization.

Editor’s note: The views expressed by the people in this story do not necessarily reflect the views of Ball Bearings.

If you took a time machine back to the 20th century in Muncie, Indiana, you would find factories booming and thriving all throughout the city, according to the Delaware County History website.

In 1880, Muncie experienced The Gas Boom. The discovery of natural gas in Indiana meant that towns like Muncie could attract industry to them with the promise of free natural gas. According to the American Oil & Gas Historical Society, this was when the Ball Brothers factory moved to Muncie, and when 162 factories came to the “Gas Belt,” which consisted of Muncie, Kokomo, Anderson, and Marion.

The upsurge of the automobile industry in the early 1900s brought even more factories to the little Indiana town. According to the Indiana Historical Society, industrialization hit its peak in Muncie in the 1950s during the post-World War II boom.

“The Midwest was one of the fastest growing places in the world,” says Michael Hicks, professor of economics at Ball State University.

Along with the rapid growth of factories came stable, high-paying jobs. Population rates grew to an all-time high, employment rates in the city began to skyrocket, and the community thrived like never before, according to the Muncie Public Library. Factories like Borg Warner, Chevrolet and Ball Brothers Co. not only provided jobs for a huge portion of the Muncie population, but also seemed to create tight-knit communities and a sense of togetherness throughout the entire city.

The boom of factories and growing industrialization in Muncie came to a quick halt around the end of the 20th century. According to the Muncie Public Library, the more than 20% of the population that had been employed by factories in the 1970s had dropped to a staggering 7% by 2000.

According to Hicks, the 12,000 factory workers that were employed in Muncie in August of 1995 decreased significantly to 3,900 factory workers that were employed in Muncie in January of 2020.

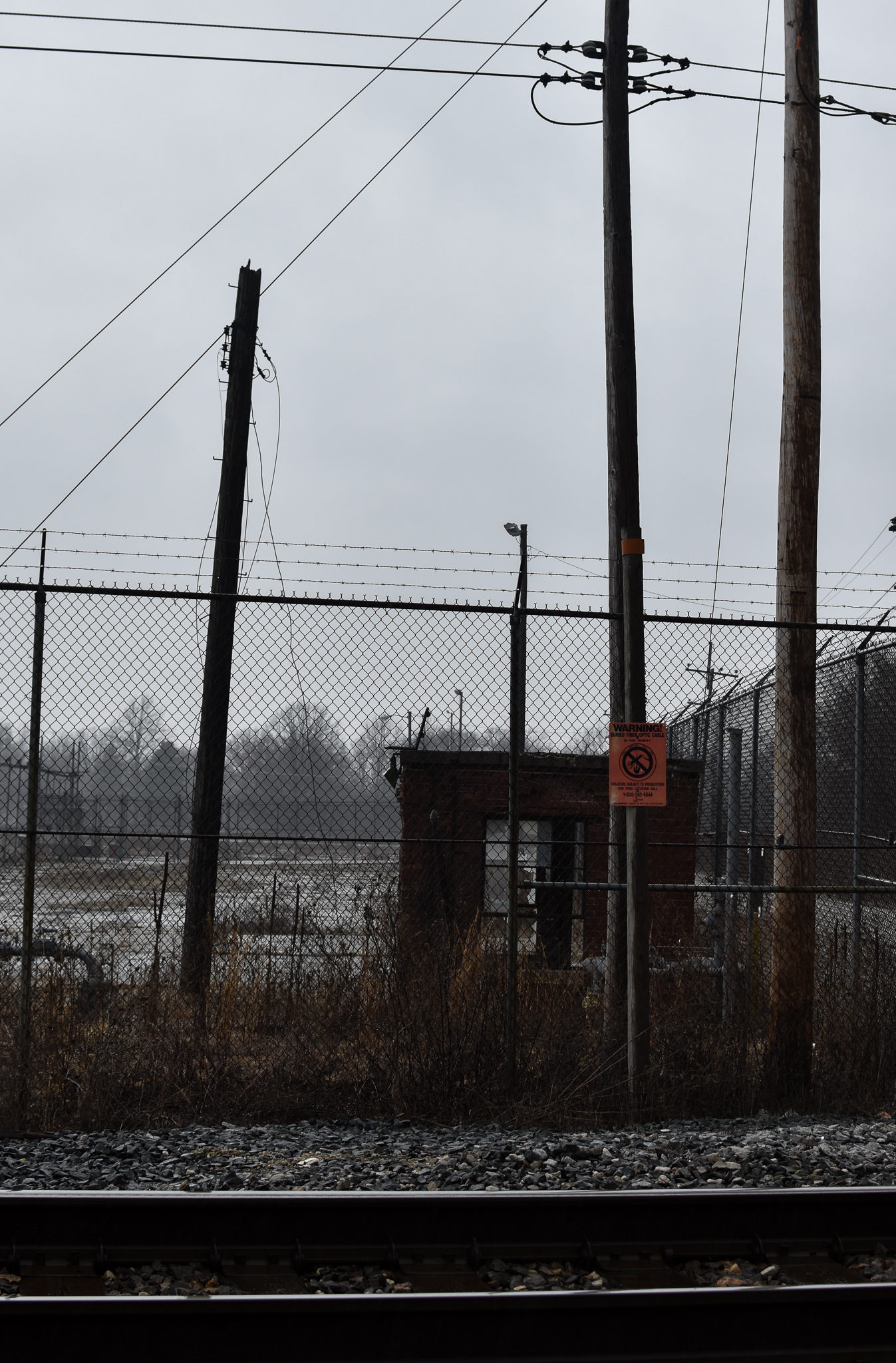

The Muncie Chevrolet plant that employed more than 3,000 people closed its doors permanently in 2006. Borg Warner, an automotive manufacturer that employed nearly 4,000 people, followed suit in 2009.

Muncie resident Rick Shirk worked at the Muncie Borg Warner plant for 32 years. He spent the majority of his life working within the 1.1 million square feet of the plant. Rick says it was the high starting wages and unbeatable benefits that initially drew him to the factory. Fortunately for him, Rick retired just three months before Borg Warner closed its doors in July 2009.

“I was one of the lucky ones. Not everyone was that lucky,” Rick says.

Rick left Borg Warner not because of the impending shutdown, but rather because things were starting to change, including the factory’s decision to hire women and other minority groups. Rick believes major changes like these were one reason why the factory started to decline so rapidly. He knew he had the capability to leave before things at the factory really took a turn for the worse, so that’s exactly what he did. He says it wasn’t a shock to anyone when they announced the factory was closing, but that didn’t make it any less difficult.

Rick says working at the factory was a lot of fun when he first started in 1973, at the age of 22.

“In the summertime, it’d be so hot. We used to fill up buckets with water balloons and we’d sneak up and hit each other in the back with them,” he says. This stopped later on, Rick says, because of policy changes.

Rick emphasizes to anyone who asks about his time at Borg Warner that life at the factory was anything but clean. Despite the employment of cleaning crews, the use of oil in the plant created thick layers of dirt and grime on most of the surfaces. The workers would come home after long shifts reeking of oil and sweat. Over the years, he says, the factory installed ventilation and it helped somewhat with this problem.

“Working at the factory was never a clean job. You could look down the aisles and see the oil mist just lingering in the air,” Rick says. “It was everywhere.”

Throughout his time at Borg Warner, Rick filled many different positions. He operated numerous types of machinery and moved around from sector to sector. In other words, he knew the ins and outs of the factory just about better than anybody. Although he wasn’t laid off like some as a result of the shutdown of Borg Warner, the closing of the plant was still difficult for him to witness.

“The closing of factories around Muncie has killed a huge part of the city,” Rick says.

Hicks agrees that the jobs lost by the closing plants were a devastating blow to the community, not just economically, but also socially.

“The things that sustain a community are not factory jobs, but the relationships we have with other people, which are greatly enhanced by jobs,” Hicks says.

You don’t have to go back too far in a history book to see how integral factories were to the growth and development of Muncie. The shutdown of factories not only left thousands of people without jobs, but also left a gaping hole in the Muncie community.

But the effects of deindustrialization were felt all across the country, not just in Muncie. According to the Bureau of Labor Statistics, an estimated 7.5 million Americans have lost their jobs due to factories shutting down since 1980. Manufacturing employment is lower now than it has been in decades as the country continues to shift away from the industry-driven economy it once was.

If you took a drive around Muncie now, it would look a lot different than it did back in the mid-20th century. Factories that were once flourishing are now abandoned and sit in empty lots, left to rot and decay.